Engineering Design & Fabrication

Innovation comes standard.

Engineering Design & Fabrication

Innovation comes standard.

Leading The Industry.

Our founder, Jeff Wilson, has a mechanical and aeronautical engineering degree from California State University Long Beach with over 40 years in engineering and design experience. He has worked for companies such as Hughes Aircraft, American Hospital Supply and Hewlett Packard. Mr. Wilson has also consulted for Bell Helmet, NASA, Disney, Universal, Icon Airplanes, Flowline, and others. Jeff Wilson has been operating his engineering firm for over 27 years with focus on mechanical, aerospace, structural and electrical designs. Currently Jeff has over 45 patents to his name.

Engineered, Tested & Built In America.

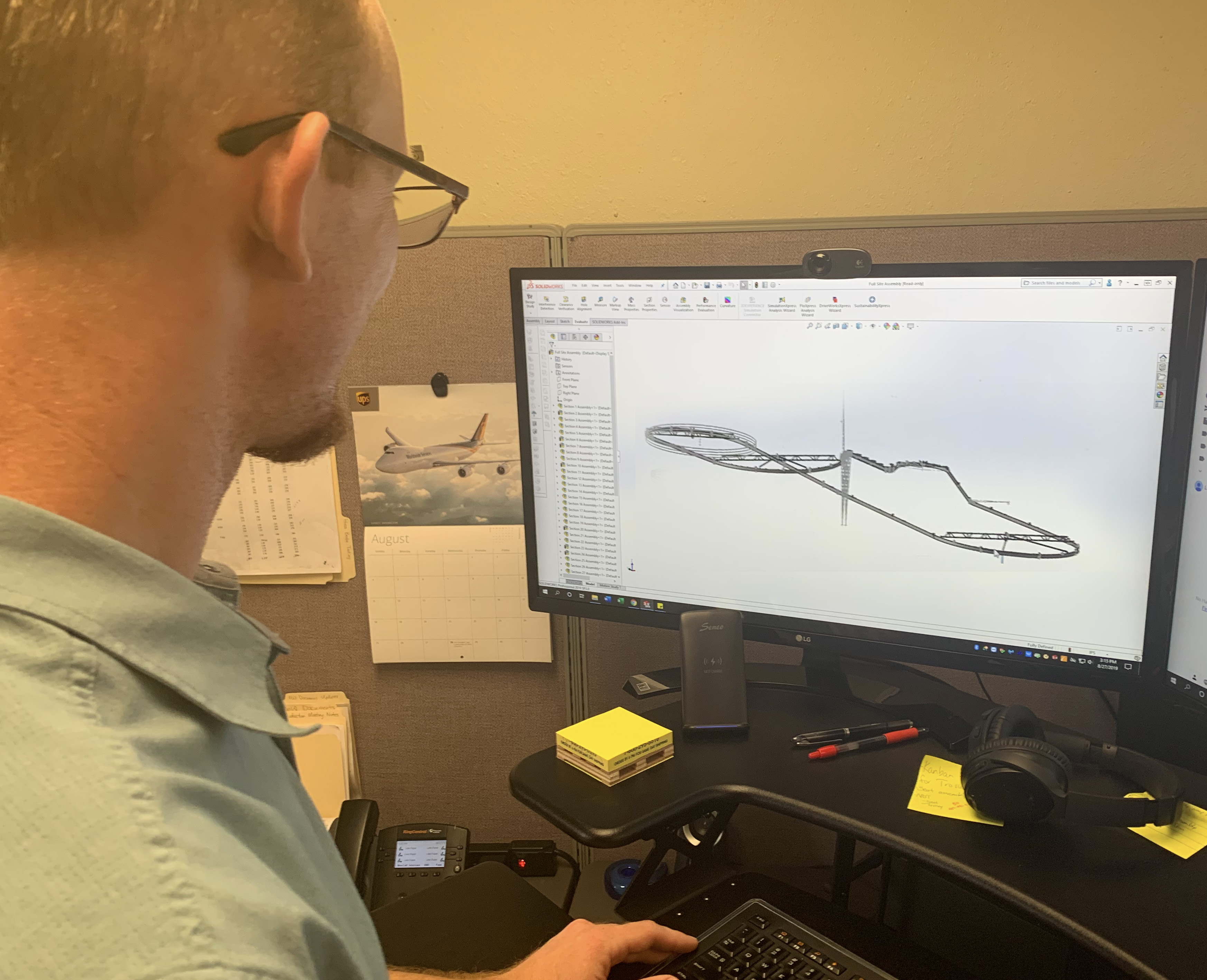

Today Extreme Engineering is recognized as the industry leader, supporting amusement ride manufacturers and A&E firms, with creative, turnkey product development solutions and manufacturing support. All of Extreme Engineering’s designs exceed industry standards such as CE, ASTM, EN, TUV and can meet CSEI. Currently our design firm has over 45 patents, such as magnetic braking solutions on suspended roller coasters, aerospace designs on fighter jets, automatic belay devices to decelerating components used on funiculars, trams and ziplines.

State Of The Art Factory.

Our firm has talented design engineers with offices in both California and Texas. Extreme Engineering’s headquarters is outside of Dallas, Texas with over 50,000 SQ FT of state-of-the-art production and R&D facilities on 9 acres. The Texas production plant is lead by AWS certified welders with additional experts in manufacturing, horizontal integration and assembly. Our factory is operated by a rigorous quality control process and driven by a computer driven MRP system for managing tooling, assembly parts and hardware. Advanced testing methods are applied to all of the products and parts assembled in our factory.

What We Do

Mechanical Engineering

With over 4 decades of expertise in mechanical engineering and design, we can assure you the product will be built correctly, safe and precise the first time. Engineering is in our DNA. We live, breathe and build creative solutions that are either a first in the industry or a major improvement to an existing product. We got you covered.

Analysis

We don’t just build something, we test it! The most crucial step in all of our designs is detailed analysis. We make sure analysis is applied to all product designs prior to production. Our expertise in analysis procedures provides the right design for the right job.

Electrical Engineering

We partner with some of the best electrical engineers in the field. Many of our product designs involve electrical hardware development, software development and electrical testing. If your product design requires electrical engineering we can manage this for you.

Prototyping

Quick prototyping allows our customers to ensure the function, design and aesthetics of their product design. We can offer a full scale prototype to a scaled 3D printed or CNC first article. We work with some of the latest technologies available in providing accurate prototypes that help our customers visualize their reality.

Production

Our production facility can accommodate high-volume, precision products and parts at competitive rates. From transport trailers for expensive airplanes, roller coasters, tractor attachments, custom brackets, support columns to funiculars, we can build it all! We can easily ship anywhere in the world with the Port of Houston, one of the world’s largest ports, only hours away from our factory. With our AWS welders, expert assembly team, process engineers and project managers we can deliver the best products in the world in a timely manner.

Atomic Golf

Extreme Engineering’s collaboration with Atomic Golf has led to the development of state-of-the-art golf ball launching cannons, providing guests of all ages with an exhilarating way to launch golf balls onto the driving range.

LF Studios

LF Studios has teamed up with Extreme Engineering, renowned for its expertise in fabrication and engineering design, to create a stunning steel substructure for a massive pirate ship. Arrr!

Treasure Hunt: The Ride

Extreme Engineering was contracted by both Sally Dark Rides and Daniels Wood Land to design and fabricate a motion floor gag for their pre-show to the award winning dark ride attraction, Treasure Hunt: The Ride, located in Monterey, California.

Dollywood’s Wildwood Grove Tree

Extreme Engineering partnered with Life Formations on fabricating Dollywood’s interactive tree at Wildwood Grove.

San Diego Symphony

Extreme Engineering was subcontracted to help on the construction and fabrication design of the all-new San Diego Symphony located at the Port of San Diego.

Volcano Bay Suspension Bridge

Extreme Engineering connected the dots for both a waterpark supplier and waterpark operator in the design and fabrication of Volcano Bay’s suspension bridge.

Silver Dollar City

Extreme Engineering was contracted to value engineer and fabricate the flume channel for Silver Dollar City’s Mystic River Falls Flume Ride.

Trans Studio Bali

Extreme Engineering was subcontracted to help on the construction and fabrication design of a the mine cart gag for Trans Studio Bali’s “Temple Raider” stunt show.

JW Marriott

Extreme Engineering was contracted by JW Marriott to design, build and install a high-class climbing attraction that blended in with their rooftop experience.